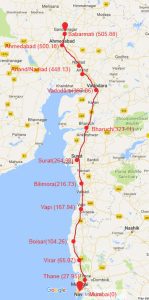

The TBM Mumbai-Ahmedabad Bullet Train project has achieved a significant breakthrough with the anticipated arrival of a crucial tunnel boring machine on September 24, 2025. After months of uncertainty, this development marks a pivotal moment for India’s most ambitious high-speed rail infrastructure project, particularly for the challenging undersea construction work beneath Thane Creek.

The arrival of this specialised equipment represents more than just machinery reaching Indian shores – it symbolises the resolution of complex international logistics challenges that had previously stalled progress on the underground sections of this transformative transportation corridor.

Also Read: TBM Mumbai-Ahmedabad Bullet Train

Also Read: TBM Mumbai-Ahmedabad Bullet Train

Other: BJP Supports SIR

Overcoming International Logistics Challenges

The journey of the TBM Mumbai-Ahmedabad Bullet Train equipment to Mumbai has been fraught with complications. Previously stranded in Chinese ports due to clearance delays, these massive machines are essential for excavating the 21-kilometre underground stretch that will connect Bandra-Kurla Complex to Shilphata in Maharashtra.

The tunnel boring machines, manufactured by German engineering firm Herrenknecht, had faced bureaucratic hurdles that threatened to delay the entire undersea tunnel construction timeline. However, diplomatic negotiations and alternative logistics arrangements have finally paved the way for their release and subsequent transportation to India.

These sophisticated machines are specifically designed for the unique geological conditions beneath Thane Creek, where they will operate at depths ranging from 25 to 57 meters below ground level. Their arrival on September 24, 2025, signals the beginning of one of India’s most technically challenging infrastructure undertakings.

Technical Specifications and Capabilities

The TBM Mumbai-Ahmedabad Bullet Train machinery represents cutting-edge tunnelling technology. These mixshield tunnel boring machines are engineered to handle the diverse geological conditions encountered in the Mumbai metropolitan region, from soft marine sediments to harder rock formations.

Each machine measures approximately 13 meters in diameter and stretches over 100 meters in length, making them among the largest tunnel boring machines ever deployed in India. Their sophisticated design allows for simultaneous excavation and tunnel lining installation, significantly accelerating construction timelines while maintaining the highest safety standards.

The machines are equipped with advanced navigation systems, real-time monitoring capabilities, and environmental protection features crucial for working beneath the ecologically sensitive Thane Creek area. Their precision engineering ensures minimal disturbance to the marine ecosystem above, including the protected flamingo sanctuary and surrounding mangrove forests.

Thane Creek Undersea Construction Strategy

The TBM Mumbai-Ahmedabad Bullet Train project’s most challenging aspect involves constructing a 7-kilometre undersea tunnel beneath Thane Creek. This unprecedented engineering feat requires meticulous planning and execution, with environmental conservation as a primary concern.

The construction strategy employs a twin-tube design that will accommodate both up-line and down-line tracks within a single tunnel structure. This innovative approach reduces the environmental footprint while maintaining operational efficiency for high-speed rail services.

Two tunnel boring machines will work simultaneously from opposite ends, meeting midway beneath Thane Creek in a complex procedure known as a breakthrough. This technique demands extraordinary precision, as alignment errors of even millimetres could compromise the entire tunnel’s integrity.

Environmental Conservation Measures

The TBM Mumbai-Ahmedabad Bullet Train undersea tunnel project prioritises environmental stewardship. By constructing the tunnel deep beneath Thane Creek, the project preserves approximately 12 hectares of mangrove forests that would otherwise require clearance for surface construction.

The tunnel’s depth ensures minimal disturbance to the creek’s ecosystem, protecting the flamingo sanctuary and maintaining the natural habitat for various marine species. Advanced monitoring systems will track any potential environmental impacts throughout the construction process.

Waste management protocols have been established to handle excavated material responsibly, with plans for beneficial reuse in land reclamation or construction projects elsewhere. The TBM Mumbai-Ahmedabad Bullet Train project sets new standards for environmentally conscious infrastructure development in sensitive coastal areas.

Construction Timeline and Methodology

Following the September 24, 2025, arrival, the TBM Mumbai-Ahmedabad Bullet Train equipment will undergo comprehensive assembly and testing procedures. Site preparation work has been ongoing at the launching shafts, ensuring readiness for immediate deployment once the machines are operational.

The construction methodology combines tunnel boring machine excavation for 16 kilometres with the New Austrian Tunnelling Method (NATM) for the remaining 5 kilometers. This hybrid approach optimises efficiency while addressing varying geological conditions along the route.

Excavation work is expected to commence in the fourth quarter of 2025, with tunnelling operations continuing around the clock to maintain project schedules. The TBM Mumbai-Ahmedabad Bullet Train tunnelling phase represents approximately 18 months of intensive construction activity.

Economic Impact and Strategic Importance

The TBM Mumbai-Ahmedabad Bullet Train project extends far beyond transportation infrastructure, representing a catalyst for economic transformation across the Mumbai-Ahmedabad corridor. The undersea tunnel construction alone creates thousands of specialised employment opportunities while fostering technology transfer and skill development.

Regional connectivity improvements will reduce travel times between Mumbai and the

Investment in the TBM Mumbai-Ahmedabad Bullet Train infrastructure positions India as a regional leader in high-speed rail technology, potentially attracting similar projects and establishing expertise that can be exported to other developing nations.

Future Implications for Indian Infrastructure

The successful deployment of the TBM Mumbai-Ahmedabad Bullet Train tunnel boring machines establishes important precedents for future underground construction projects across India. The technical expertise gained from this challenging undertaking will benefit subsequent metro rail, highway tunnel, and water infrastructure projects.

This project demonstrates India’s commitment to adopting advanced construction technologies while maintaining environmental responsibility. The September 24, 2025, arrival marks not just equipment delivery but the beginning of a new era in Indian infrastructure development capabilities.

The TBM Mumbai-Ahmedabad Bullet Train project’s success will influence policy decisions regarding future high-speed rail corridors, potentially accelerating similar projects connecting other major Indian cities and establishing a comprehensive national high-speed rail network.